There is nothing—and I mean nothing—more heartbreaking in this hobby than hearing that sickening “RIP” sound.

You spent $40 on premium yardage. You spent three hours tracing your design. You finally turn on your gun, run your first line, and suddenly you’re looking at a massive hole in your canvas. I’ve been there. I have cried over shredded Monk’s cloth more times than I care to admit.

If you are currently staring at a ruined rug and asking, “Why is my tufting cloth tearing?” take a deep breath.

You didn’t break the gun, and you aren’t bad at this. You just missed a variable.

Tufting is not just art; it is mechanics. When your cloth rips, it is simply physics telling you that something is fighting against the needle.

In this guide, I am going to walk you through the 5 most common reasons why your tufting cloth is tearing and exactly how to fix them, so you can get back to making beautiful rugs.

If I had a dollar for every beginner who asked me “why is my tufting cloth tearing,” only for me to find out their fabric was sagging like a hammock, I could retire today.

Here is the golden rule of tufting: Tension is everything.

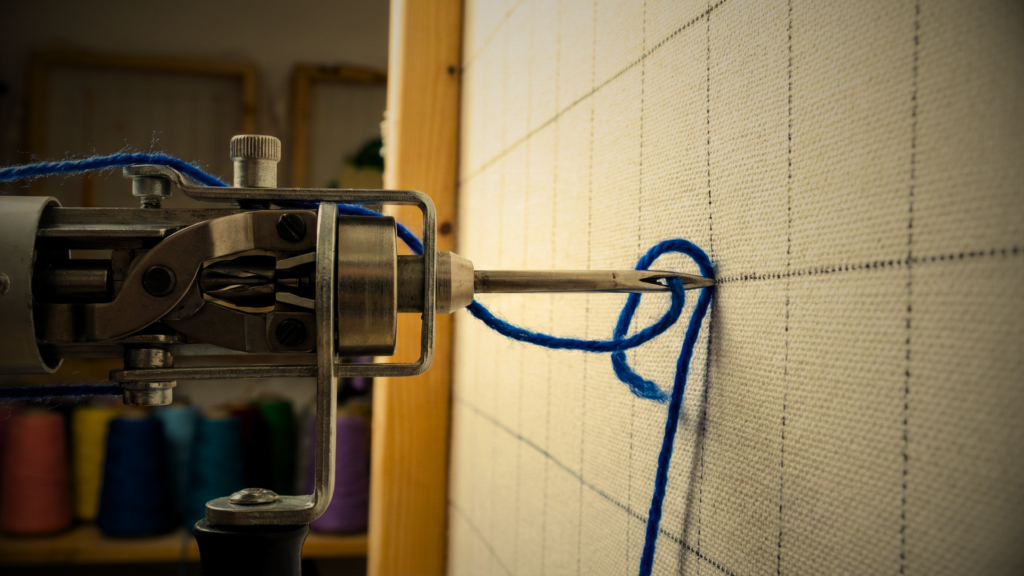

When your tufting gun fires, that needle is moving in and out at incredible speeds. If your fabric is loose, the needle doesn’t punch through the fibers cleanly. Instead, it catches the fabric, pushes it backward, and then drags it. That drag creates the tear.

How to Diagnose It

Before you even touch your gun, walk up to your frame. Flick the cloth with your finger.

Does it wobble and ripple? It’s too loose.

Does it sound like a tight snare drum? That’s what we want.

If you are wondering why is my tufting cloth tearing even though you stretched it, you probably didn’t stretch it enough. You need to pull that fabric until your fingers hurt. It should be terrifyingly tight.

The Fix: Upgrade Your Grippers

Are you using staples or nails? Stop. As you tuft, the vibration loosens them. If you want to stop asking why is my tufting cloth tearing, you need to install Carpet Tack Strips (the kind with the sharp red nails) on your frame. They hold the fabric under extreme tension and allow you to re-stretch it constantly as you work.

We need to have a serious talk about fabric. I know Burlap is cheap. I know you saw it at the craft store for $5 a yard. But listen to me: Burlap is the enemy.

Burlap is made of jute. It is brittle. It has no elasticity. When the thick needle of an AK-1 cut-pile gun hits a strand of burlap, that strand snaps. Once one strand snaps, the whole grid falls apart, and that is exactly why is my tufting cloth tearing instantly.

You need 100% Polyester Primary Tufting Cloth. Usually, this is gray (or white) with yellow/black grid lines woven into it.

If you are using cotton canvas, linen, or denim, you are making your life harder. Those fabrics are too stiff. The number one answer to “why is my tufting cloth tearing” is simply that you brought a knife to a gunfight—or rather, a piece of fragile jute to a power-tool fight.

Your tufting gun is a machine. It fires at a constant rate. Let’s say it punches 20 times per second.

If you catch yourself asking why is my tufting cloth tearing specifically when you are trying to do detailed curves or small lines, this is usually the culprit. You are slowing down your hand to be “careful,” but you forgot to slow down the gun.

Check the speed dial at the bottom of your tufting gun handle.

For Beginners: Turn it all the way down to the lowest setting. This gives you time to think.

The Rhythm: You need to move your hand in a fluid, confident motion. Don’t linger. If you stop moving your hand, take your finger off the trigger immediately.

Sometimes, you are doing everything right. Your tension is drum-tight. You have premium grey cloth. Your speed is perfect. And yet, you are still screaming, “Why is my tufting cloth tearing?!”

It might be a factory defect.

The metal needle on tufting guns (especially the budget ones) can sometimes have a tiny, microscopic scratch or “burr” on the tip. It feels like a snag on a fingernail. Every time that needle enters the cloth, that tiny metal burr catches on a fiber and rips it.

Turn your gun off and unplug it. Run your fingernail gently over the tip of the needle and the metal foot. Does it feel perfectly smooth? Or does it catch? If it catches, you have found the mechanical reason why is my tufting cloth tearing.

Get a piece of fine-grit sandpaper (400 to 800 grit). Gently sand the tip of the needle and the edges of the metal foot until they are buttery smooth. This takes 30 seconds but can save you hundreds of dollars in ruined cloth.

This is a sneaky one that experienced tufters often miss.

Your gun pulls yarn from the cone. That yarn needs to flow freely. If the yarn gets snagged on your furniture, caught under the frame, or if the cone falls over, the gun creates tension on the yarn.

When the gun pulls hard on the yarn and the yarn doesn’t move, the gun pulls itself forward instead. This jerks the needle violently into the fabric.

If you notice the tearing happens suddenly or feels like the gun is “bucking” in your hand, this is likely why is my tufting cloth tearing.

I know it is frustrating. I have thrown my fair share of tantrums in the workshop. But usually, the answer to “why is my tufting cloth tearing” is a simple adjustment.

Go through this list one by one. I promise you, one of these is the culprit. Once you fix it, the tearing stops, and the fun begins.

Now, go tighten that frame and try again. You’ve got this.